https://earth-investment.com/wp-content/uploads/2021/03/iStock-936418814-1-scaled-e1615559393223-1500x1097.jpg

https://earth-investment.com/wp-content/uploads/2021/03/iStock-936418814-1-scaled-e1615559393223-1500x1097.jpg

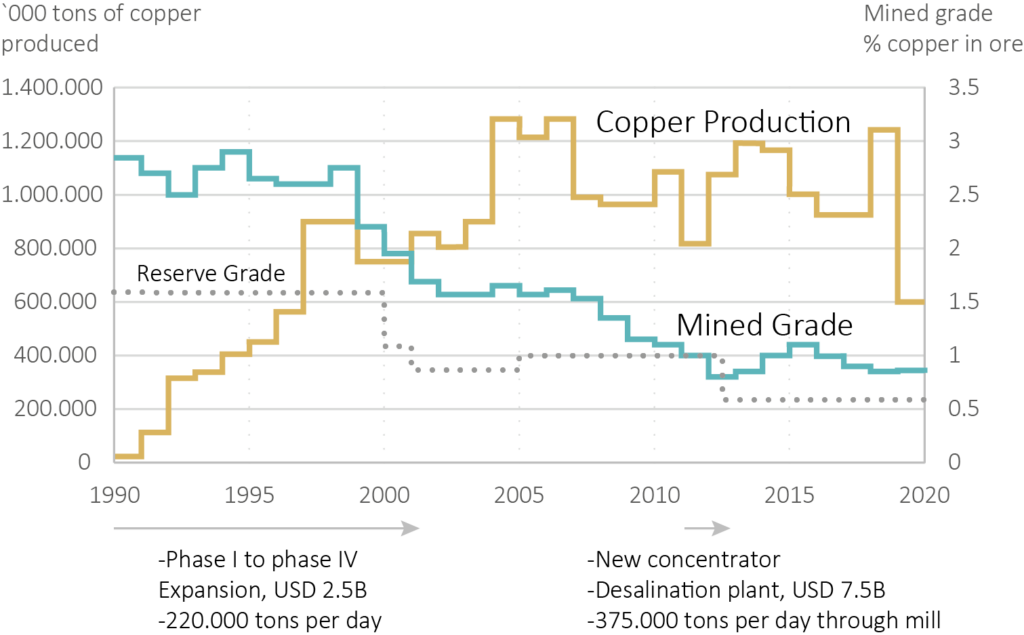

The Escondida Copper Mine, operated by BHP Billiton is the world’s largest copper mine, producing around 4-5% of the world’s copper supply. The mine is Located in the Chilean Atacama desert, around 170km Southeast of Antofagasta. Escondida is a typical Copper-Gold porphyry, a large, relatively low-grade deposit that is mined using mass mining techniques.

The mine was discovered in the early 1980s and started production via a large open pit in the early 1990s. The mine is a typical case study of how the ore grade and the volume of moved material of the world’s largest copper mines have evolved over the past decades. Most large copper mines in the Americas, as well as elsewhere on the globe, follow the same pattern, which is critical for the future copper supply.

When Escondida started production in early 1990, the mine was very rich in copper with a mining head grade of around 2.5-3% copper. The mine expanded quickly, implementing four major expansion phases until the Escondida concentrator reached daily throughput volumes of around 200,000 tons. Around 800,000 tons of copper were produced annually by the year 2000. With the richest portions of the ore body being mined around the turn of the century, the grades started to drop off quickly. The reserve grade, the grade used to calculate the future ore tonnage to be mined, was continuously adjusted downwards and is today around 0.5%, around a third of what it was when the operation started. BHP continued to expand the Escondida concentrator in order to increase mined volumes and to keep up copper production volumes to compensate for the declining grade. By doing so, BHP invested close to USD 10B to date through several expansion phases. Today, the mine processes an incredible 375,000 tons of ore per day. Since the start of the operation, mass handling and material movement have roughly tripled.

Source: ERIG, BHP, Cochilco

This case study impressively illustrates the problem the mining industry is confronted with today. Declining ore body grades require ever-increasing tonnage to be moved and processed. This requires large amounts of capital, as well as commodity prices that allow such large, earth-moving exercises to be performed in a profitable, and sustainable way.